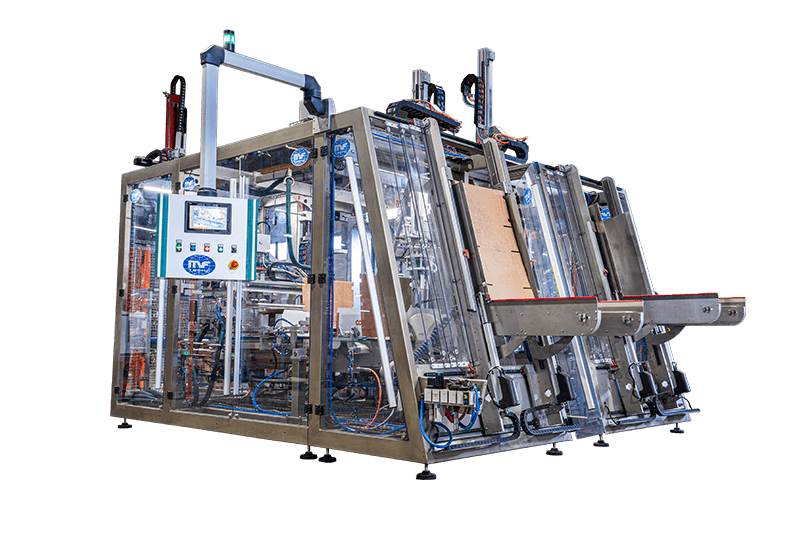

The MF TECNO Wrap Around Case Packer represents a highly reliable solution for end-of-line packaging, designed to pack products into trays, plateaus, and American cases.

The MF TECNO Wrap Around Case Packer represents a highly reliable solution for end-of-line packaging, designed to pack products into trays, plateaus, and American cases. This automatic machine forms the package directly around the product, starting from a die-cut carton that is subsequently sealed, offering a versatile and customizable solution.

The Wrap Around Case Packer is used in multiple industrial sectors, including:

Thanks to its flexibility, it can handle various types of packaging, such as:

The packages can be packed both vertically and horizontally, perfectly adapting to different production needs.

The machine can achieve productions of up to 20 boxes/min, ensuring a significant boost in production efficiency.

With numerous accessories, the case packer can easily adapt to specific customer requirements, offering tailored solutions.

The manual adjustment system allows for quick adaptation to different formats, enhancing operational flexibility.

The design is conceived to facilitate inspection and maintenance operations, reducing downtime.

With a capacity of up to 400 cartons, the elevated magazine simplifies the positioning and replenishment of cartons, optimizing workflow.

The machine can integrate:

Versatility in Product Introduction

The product insertion into the carton is carried out through:

The wrap around case packer is part of the secondary packaging process and can be easily integrated with other packaging and palletizing systems, creating complete turnkey packaging plants. This synergy allows for optimization of the entire production process, improving logistics and management.

Using a wrap around case packer offers numerous benefits, including:

It uses pre-cut cartons (flat blanks), reducing waste and cutting production costs.

The wrap around technique ensures a snug fit, reducing overall package volume and improving transport and storage.

Precise packaging ensures greater product stability, minimizing the risk of damage during transport.

Reduced material usage and increased logistic efficiency contribute to a lower environmental impact.

It can handle products of different shapes and sizes, adapting to multiple industrial applications.

The machine’s reliability, combined with dedicated customer support, minimizes downtime and ensures operational continuity.

Integrating a wrap around case packer into your production line represents a strategic choice to enhance efficiency, reduce costs, and optimize the end-of-line packaging process. With customizable solutions, high performance, and maintenance-friendly design, this machine is an ideal solution for secondary packaging in multiple industrial sectors.

Request information

Request information  Download pdf

Download pdf

There are many reasons to choose our products

Discover more

Discover more Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more