The use of palletizers in the pet food industry addresses the need to optimize production processes while improving storage and logistics operations.

It has a direct impact on productivity, cost efficiency, and product safety.

In an increasingly competitive market dominated by large players, automation, scalability, and efficiency in end-of-line packaging are critical factors for success.

This sector has been one of the fastest-growing industries in recent years.

According to projections, the global packaging market is expected to grow significantly, with annual growth rates of 5.45% between 2024 and 2032.

Investing in industrial automation helps businesses compensate for labor shortages and meet production standards demanded by the market.

In this article, we will examine:

Choosing the ideal palletizer depends on various factors, including:

The increasing demand for pet food has led to a diversification of packaging, each designed to meet specific requirements for storage, marketing, and logistics.

Packaging formats vary depending on weight and size, ranging from a minimum of 300g to a maximum of 30kg.

For dry pet food in particular, common packaging includes:

The primary factor in choosing the right palletizer is its ability to efficiently handle large volumes of goods.

Managing high production volumes without bottlenecks ensures competitiveness and the ability to meet market demand.

The pet food industry evolves rapidly, leading to the creation of various packaging types and formats. Machines must adapt quickly to new palletizing configurations and packaging formats.

Another critical consideration is the space available at the facility. A compact and easily integrable machine configuration provides a significant advantage.

Selecting the right model based on production needs ensures a quick return on investment while improving operational efficiency.

The choice of palletizer depends on the type of packaging and the specific production needs of the pet food sector.

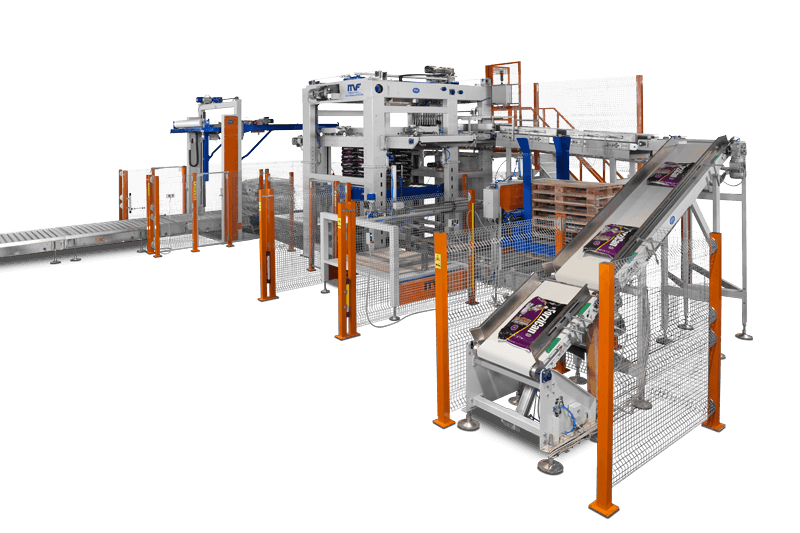

Over time, we have developed a wide range of palletizers capable of meeting the demands of a dynamic and constantly growing market.

Notable options include:

The cartesian palletizer is an ideal solution for secondary packaging.

It handles large quantities of products following a predefined workflow.

Movement along the 4 cartesian axes and rotation around its axis allows for lifting and transporting items from a platform to a pallet.

Different gripping tools are available, enabling the handling of various types of packaging, including bags, trays, boxes, drums, and cans.

Thanks to their versatility, MF TECNO cartesian palletizers are suitable for most packaging types in the pet food industry.

The choice of model often depends on the required production volumes.

The PCA Smart is designed to handle loads up to 50kg with production rates of up to 500 cycles/hour.

Extremely compact and stable, it measures just under 3 meters and can handle pallets up to 1800mm high (including the base pallet).

It is ideal for moving products in tight spaces or challenging environments.

Additionally, the machine integrates seamlessly with existing systems and turnkey solutions.

For high production needs, two options are available: the Smart Pro and the MF PCA 700 Twin.

Smart Pro: This model retains the characteristics of the standard version but offers higher productivity, reaching up to 800 cycles/hour. It handles boxes, bundles, and bags, including valve bags, open-mouth bags, and bags made from reels.

MF PCA 700 Twin: This model achieves up to 700 cycles/hour and features a dual palletizing station, enabling continuous operation. When one pallet is completed at the first station, the second station begins immediately. This allows the finished pallet to be removed without halting production.

The PSM 1500/S is a solution designed for productions of up to 1500 bags/hour, with bag formats ranging from 2kg to 50kg.

Its motorized belt orienter, lateral compactors, and high-low deposit system ensure the creation of stable, compact pallets.

The empty pallet magazine and modular structure allow for multiple assembly configurations.

The PRC 1000 is a cartesian top-loading palletizer with a compactor, offering impressive production capacities:

Like the push-type palletizer, it includes motorized lateral compactors and interlayer placement from a reel to ensure stable, organized storage.

Its intuitive interface, equipped with a PLC system and touchscreen panel, enables operators to easily manage palletizing schemes.

We have decades of experience in the pet food sector, offering both standalone projects and complete turnkey packaging solutions.

Choosing MF TECNO means partnering with a reliable, quality-focused company that produces every component of its machinery in-house.

We guarantee fast delivery times and a dedicated, reliable, and punctual customer service team.

Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more