The Wrap-around Case Packer represents an increasingly popular secondary packaging solution.

According to FMI, the Wrap-around market will grow at an annual CAGR of 2.7% over the next decade.

Although it can be applied to virtually infinite sectors, it is often used in the food & beverage, pharmaceutical, and retail industries.

Its versatility and ability to provide durable and aesthetically appealing packaging make it highly widespread in the retail sector.

It is ideal for all products requiring a high level of protection and stability during transport and storage.

It ensures that goods are hermetically sealed to minimize and prevent the risk of damage.

In this article, we will analyze:

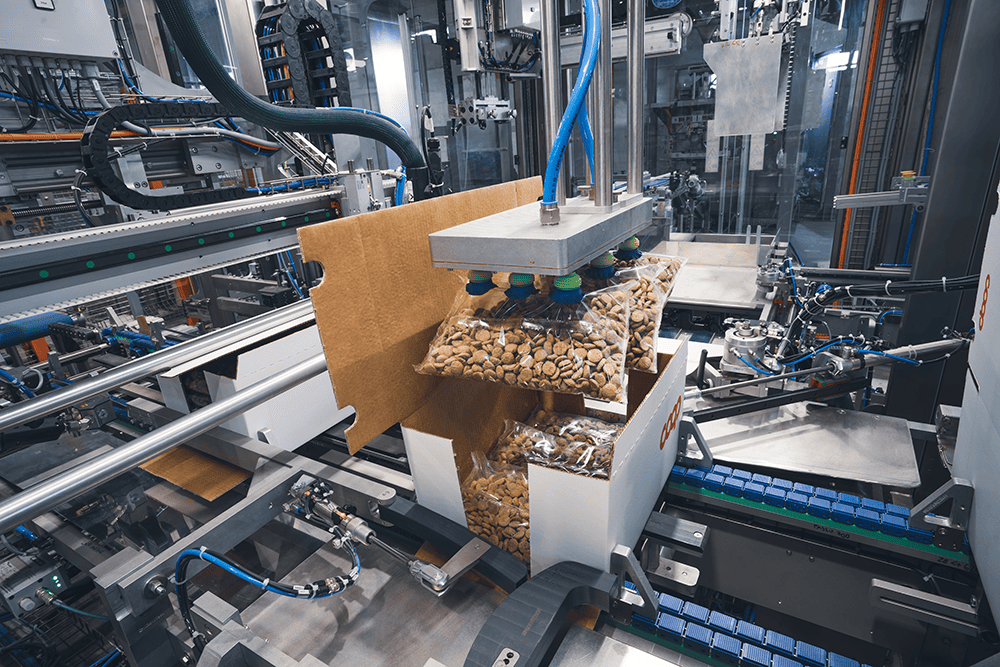

The Wrap-around Case Packer forms the packaging directly around the product using an open die-cut carton, which is then sealed with a hot melt system.

This allows the creation of customized boxes or enclosures around the products, ensuring security, protection, and stability.

Unlike other solutions, this all-in-one system reduces the total amount of carton used and increases overall efficiency, hence a carbon footprint reduction.

It meets the needs of large-scale distribution by providing various packaging types.

This machine offers several advantages, including:

Optimization of Warehouse space and logistic

It helps manufacturers, retailers, and distributors optimize supply-chain management.

The creation of perfectly squared packages that adhere closely to the product ensures better palletization.

This machine is highly versatile, allowing the handling and processing of different products, formats, and sectors.

It is extremely popular in processing consumer goods.

The Wrap-around case packer is designed to produce packaging that is ready for display and retail sale in supermarkets and stores.

It facilitates transportation and quick shelf restocking.

The ability to customize the numerous packages it processes allows easy access and minimal product handling.

This packaging solution uses fewer packaging materials, ensuring significant cost savings. In particular, it is an excellent medium-to-long-term investment as it reduces:

This investment reduces the company’s environmental footprint and allows compliance with new legislative standards (PPWR).

It helps brands present and communicate their product and image more effectively. It offers unparalleled visibility compared to other packaging machines.

This contributes to increasing the overall brand appeal against competitors and boosting total sales.

Wrap-around machines can process a higher number of cartons per minute compared to traditional systems. This increases productivity while reducing labor costs.

It ensures continuous production cycles.

Among case packers, we distinguish between the wrap-around case packer and the RSC Cartoner.

The former creates the box from flat carton stock, which is then wrapped around the product.

The latter, instead, uses a pre-glued carton, where the product is inserted into the open box using dedicated gripping heads.

Several factors should be considered when investing in a Wrap-around Case Packer.

The type of case to be processed determines the choice of the appropriate machine.

The wrap-around case packer is highly versatile and can form various types of cases, including trays, trays with lids, open top/plateaus, and carton boxes.

The type of product to be packaged is a crucial factor when choosing between different machines.

Generally, Wrap-around Case Packers are suitable for products with regular shapes, stackable items, and multipack or display packaging.

These include doypack bags, pillow packs, square-bottom bags, and plastic bottles, commonly found in the food, beverage, pet food, and pharmaceutical sectors.

On the other hand, RSC American cases are recommended for heavier, irregular, and fragile products who need to be only transported from the factory to their final destination.

These include large bags, glass bottles, beverage cans, etc.

Production requirements and the level of automation needed are also key considerations.

The Wrap-around Case Packer is best suited for production environments requiring high productivity, scalability, and automation.

Another important factor is the initial investment.

A comprehensive evaluation should consider not only the upfront cost but also the ROI, material savings, labor reduction, and overall efficiency improvements.

They are highly versatile, allowing them to adapt to different industries, applications, and box types.

MF TECNO case packers offer versatility, reliability, and high productivity.

Their modular design allows adaptation to various customer requirements, providing tailor-made solutions.

They are designed for different types of packaging, including trays, open top/plateaus, RSC American cases, pre-cut cartons and Q&T cases.

The ergonomic design, touchscreen control panel, and 360° accessibility significantly facilitate operator interventions.

It ensures high productivity, reaching cycles of 20 tray and lid boxes per minute.

The inclusion of different closing modules, an automatic carton magazine, and various gripping systems helps optimize the production cycle.

The in-house manufacturing of each individual component ensures competitive delivery times and efficient after-sales service.

We specialize in manufacturing complete packaging systems.

We offer turnkey solutions covering product transportation, packaging, and secondary packaging.

Thanks to continuous investments in research and development, we have created a wide range of machinery available to our customers.

Each model is entirely designed, produced, assembled and tested in our facility.

This allows us to develop tailor-made solutions to meet different project requirements and specifications.

A single point of contact takes full responsibility for every phase of the project, from design to after-sales support.

An international company with over twenty years of experience in the sector.

This ensures fast delivery times and punctual, efficient after-sales service, guaranteeing a quick return on investment (ROI).

Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more