The Tubular Forming Machine (FFS) is a valid option for large packaging (up to 50 kg) from a tubular reel.

Appreciated and preferable to VFFS when it is necessary to combine requirements such as high productivity, aesthetic, bag strength and small footprint.

Fully automated system characterized by three operating stations.

Thus, by three distinct stages prepared:

According to Future Market Insight (FMI), the sector will register significant growth of 5.1 percent annually. The industry si projected to reach $17.9 billion by 2032, up from $11.5 billion in 2022.

In this guide we will analyse and explain in detail:

Difference between Vertical Packaging Machine and Tubular Forming Machine

The main difference between these two types of machines comes from the reel.

If vertical packaging machines allow bags to be formed from flat reel, the forming machine uses a tubular reel.

This implies the following differences:

This type of sealing also prevents the product from getting cought in he orners of the bag when unloading.

The tubular forming machine is particularly versatile.

In fact, the features listed above allow the machine to be applied in a different sectors.

Its high production rates, special propensity for packaging large formats and ability to process granular and powdery products make it an ideal choice for packaging:

We have carried out installations of tube forming machines at major companies in Italy and worldwide.

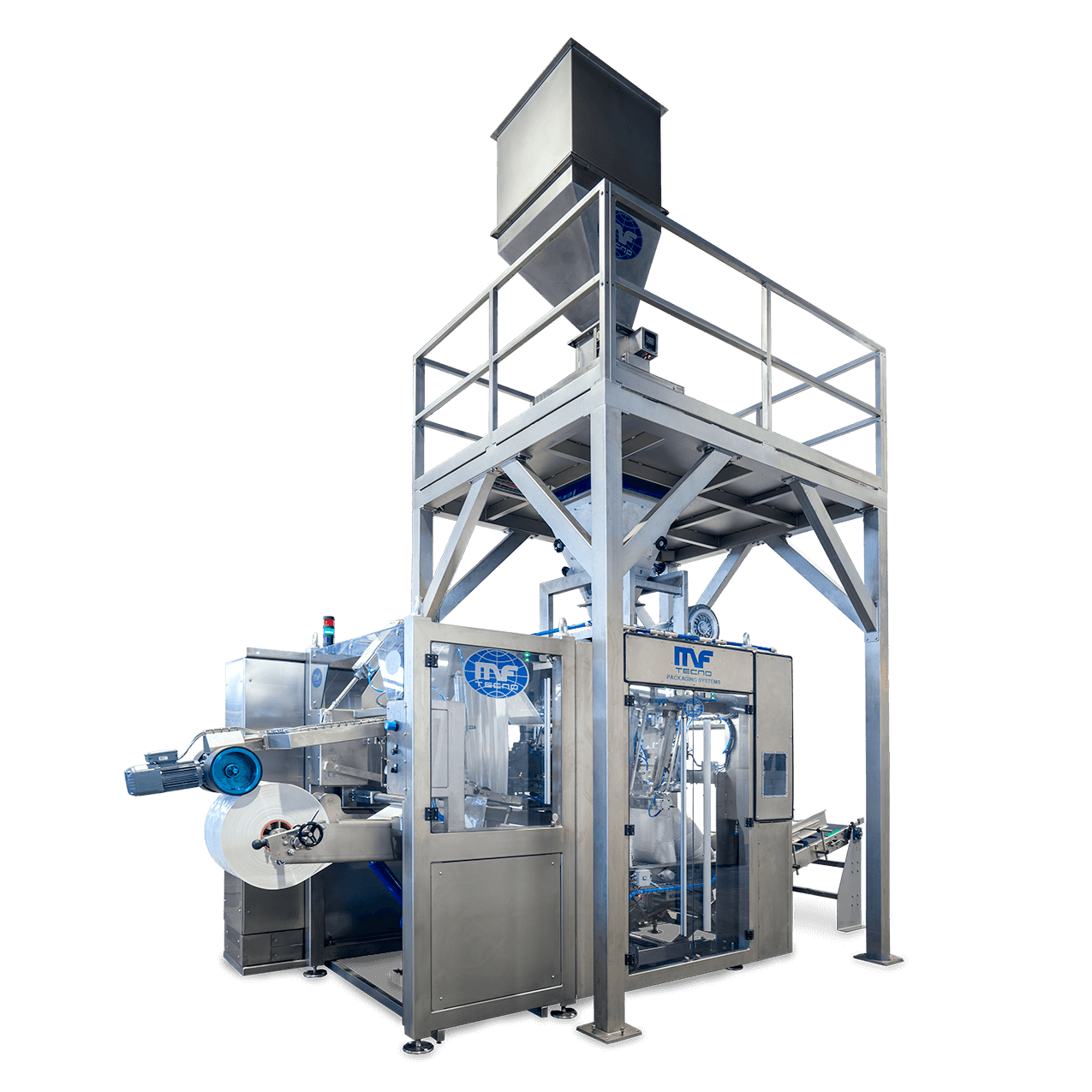

Our tubular forming machine, the MF TUBE, is the ideal solution for processing flowing, powdery and granular products.

Depending on the characteristics of the product, it can reach a production of 2000 bags/hour for large formats.

The machine, entirely made of stainless steel, can handle a wide range of both food and corrosive products.

The forming machine is provided with three operating stations:

All operations are easily managed by the operator via PLC.

Due to its small footprint and consequent space optimisation, the machine is suitable for installation in even the tightest production enviroments.

They often included in complete packaging plants, including palletising systems and pallet wrappers.

Choosing MF TECNO means putting your trust in a solid and efficient company.

You can count on:

We have decades of experience in the construction of complete packaging plants and installations worldwide.

Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more