The use of palletizers in the Pet Food industry addresses the need to optimize production processes and improve storage and logistics. It has a direct impact on productivity, cost efficiency, and product safety.

In an increasingly competitive market dominated by major players, automation, scalability, and efficiency in end-of-line packaging processes have become essential.

This is particularly crucial in the Pet Food sector, one of the fastest-growing industries in recent years.

Investing in Industrial Automation

Global forecasts predict significant growth in the sector, with an annual growth rate of 5.45% from 2024 to 2032.

Adopting industrial automation helps offset labor shortages and align with production standards required by the market.

In this article, we will explore:

- Key factors to consider when selecting a palletizer

- The different types of palletizers available

Key Factors to Consider When Selecting a Palletizer

Choosing the ideal palletizer depends on various factors, including:

- Type of packaging

- Production requirements

- Flexibility

- Available space

- ROI (Return on Investment)

Type of Packaging

The growing demand for Pet Food has led to a diversification of packaging types, each designed to meet specific requirements for preservation, promotion, and logistics. Packaging ranges from 300 grams to 30 kilograms, and common types include:

- Stand-up pouches

- Pillow bags

- Woven polypropylene bags

- Paper bags

- Bulk bags

- Cartons grouping multiple bags

- Shrink-wrapped bundles

Production Requirements

The first key element is the ability to efficiently handle high volumes of goods. Managing large-scale production without bottlenecks ensures competitiveness and meets market demand.

Flexibility

The rapid evolution of the industry leads to the creation of diverse packaging types and configurations. Machines must quickly adapt to new palletizing layouts and packaging formats.

Available Space

Factory space is another critical consideration. A compact, easily integrable machine is a significant advantage.

ROI

Selecting the right model for your production needs ensures a quick return on investment while improving operational efficiency.

Types of Palletizers

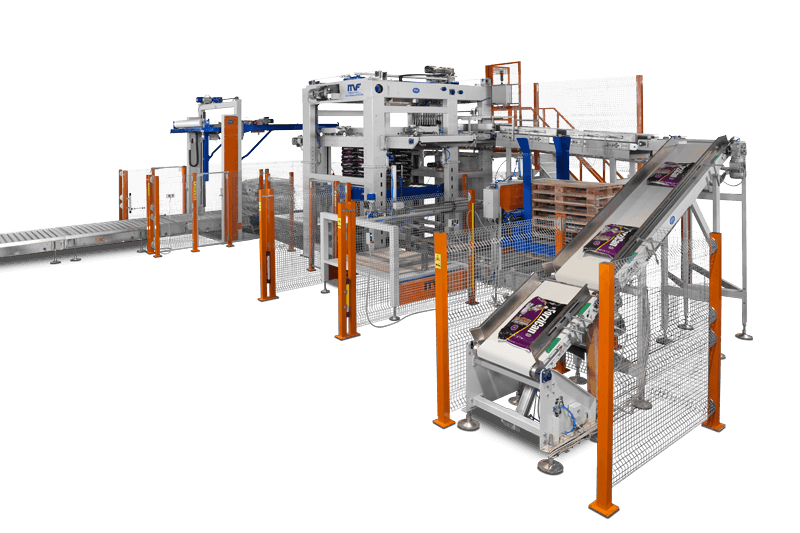

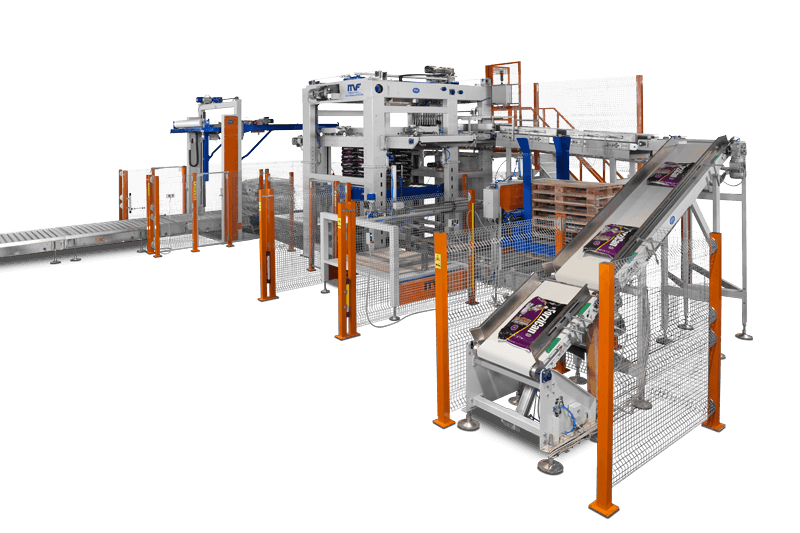

The choice of palletizer depends on the type of packaging and specific production requirements of the Pet Food industry. Over the years, we have developed a wide range of palletizers to meet the demands of this dynamic, fast-growing market.

Our offering includes:

- Cartesian palletizers

- Push-type palletizers

- Top-loading palletizers

Cartesian Palletizers

Ideal for secondary packaging, Cartesian palletizers handle large quantities of products following a predefined pattern. Their movement across four Cartesian axes, combined with rotation around their axis, allows for precise lifting and transport from the platform to the pallet.

Different gripping tools are available to handle a variety of packaging types, including bags, trays, boxes, drums, and cans. Thanks to their versatility, MF TECNO Cartesian palletizers are suitable for most packaging types in the Pet Food sector.

Cartesian Palletizer for Medium Production

The PCA Smart is designed to handle loads up to 50 kg with production rates of up to 500 cycles/hour. Compact and stable, it has dimensions under 3 meters and can handle pallets up to 1800 mm in height (including the pallet). It is perfect for confined spaces and challenging environments and integrates easily with existing systems.

Cartesian Palletizer for High Production

For high-production needs, we offer two models: the Smart Pro and the MF PCA 700 Twin.

- Smart Pro: Maintains the characteristics of the standard version while ensuring higher productivity, reaching up to 800 cycles/hour. It handles boxes, bundles, and various types of bags, including valve bags, open-mouth bags, and bags from reels.

- MF PCA 700 Twin: Achieves up to 700 cycles/hour, thanks to its dual palletizing station. This setup allows uninterrupted operation, as the second station begins while the first pallet is being removed.

Push-Type Palletizers

The PSM 1500/S ensures production rates of up to 1500 bags/hour for formats ranging from 2 to 50 kg. It features a motorized belt orienter, side compactors, and high-low depositing systems for stable and compact pallets. The modular structure and empty pallet magazine enable multiple configurations.

Top-Loading Palletizers

The PRC 1000 is a Cartesian top-loading palletizer with a compactor, achieving impressive production capacities:

- 1200 bags/hour with single grip

- 2000 bags/hour with double grip

Like the push-type model, it includes motorized side compactors and an interlayer system made from reels for stable and orderly storage. Its intuitive interface, featuring PLC and a touch screen, simplifies operation.

Why Choose MF TECNO

With decades of experience in the Pet Food industry, we specialize in both individual projects and complete turnkey packaging systems.

Choosing MF TECNO means partnering with a reliable, quality-focused company that produces every component of its machinery in-house. We offer fast delivery times and dedicated, dependable customer service.

FREE QUOTE

FREE QUOTE  Machinery

Machinery Open Mouth Bagging machines

Open Mouth Bagging machines Vertical packaging machines - VFFS

Vertical packaging machines - VFFS FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information