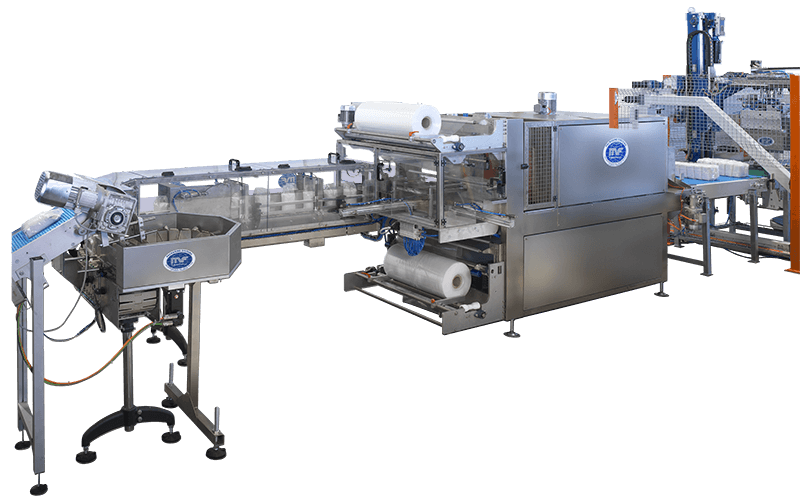

The Automatic Shrinkwrapper is a machine that takes action in the secondary packaging stage to create a compact package that protect multiple units of product.

It is usually an integrative part of production lines and complete plants and is specially designed to connect the packaging system to the palletising system.

Ideal for all industrial activities where a significant amount of packed goods need to be handled.

Designed for shrink wrapping of bags, bricks and square-bottom cartons. Especially popular in the food, beverage, cosmetics and pharmaceutical industries.

According to fmi, the shrink machinery sector will have a major development in the near future. With a CAGR of 7.2% by 2032.

Packaging is applied in two stages.

During the first one, the shrink wrapper is equipped with a bundle preparation module, which sorts the incoming material according to the configuration specified by the customer.

In the second, we have the wrapping with shrink film and the passage through the shrink oven. This guarantees perfect adhesion of the film to the packs and a consequent reduction in the volume of the bundle.

The coating thus formed provides an effective barrier effect to protect the product and an improved storage and handling process.

In the following we will analyse:

- Automatic Shrink Wrapping Machine advantages

- MF Tecno shrink wrappers

- Our installations

- MF Tecno Packaging systems

Automatic Shrink Wrapping Machine Advantages

The shrink wrapping process offers many advantages, among them:

Versatility - The shrinkwrapper allows different products and items with irregular and non-uniform shapes to be processed.

Space saving - The packaging of multiple articles and product units results in significant space savings and an overall optimisation of warehouse and storage processes. The packaging material can be significantly reduced by up to 50 per cent of its original size.

Resistance and impermeability – Wrapped items are effectively protected from external agents and conditions. The special characteristics of the film used ensure a longer life and overall protection of the package, which contributes to the longevity of perishable products.

Cost efficiency – The choice of an automatic shrinkwrapper allows products to be bundled and packaged while optimising packaging costs in comparison with cardboard box type solutions.

Reducing labor costs – The option of an automated packaging solution can considerably reduce labour costs.

MF Tecno shrink wrappers

MF Tecno shrinkwrappers are reliable and high-performance solutions for creating bundles of any form.

Especially suitable for packaging salt, sugar and flour.

Suitable for medium-high production, reaching 10 bundles per minute.

These are continuous motion packaging machines developed for bags, bricks and cartons that arrive horizontally or vertically on the infeed conveyor.

Electronic regulation of heat-shrink temperatures is also provided, giving the operator complete control.

Made entirely of stainless steel, they are composed of 3 modules:

- Bag receiving carousel and sorting device provided with a diverter to distribute parcels over two or more rows.

- Automatic stacker with the function of grouping and stratifying the product.

- Sealing unit with shrink film sealing around the bundle.

- Hot-air shrink oven with bundle feed on conveyor belt.

Our installations

Our Vertical Shrinkwrapper was the protagonist of a major turnkey project for sugar packaging in Algeria.

A system capable of processing 38,400 bags of 1 kg/hour and comprising 8 lines, each consisting of:

- Multi-head electronic weighing machine

- Packaging machine MF 52 Speedy

- Carousel system

- Shrink Wrapper Bundlee V

A complex project comprising eight series production lines connected by a conveyor belt.

The high productivity required led to the choice of a high-performance solution such as the MF 52 Speedy, ideal for high production.

A carousel system turns the bags vertically, allowing Bundlee V to create bundles later.

MF Tecno Packaging systems

For over 20 years we have specialised in complete systems and turnkey solutions. Packaging, secondary packaging and palletising systems.

A single contact person handling all phases of the project, from the preliminary to the final installation phase.

Our machine park is our own production, in every component.

In-house production ensuring extremely competitive delivery times and prompt technical support at your service.

FREE QUOTE

FREE QUOTE  Machinery

Machinery Open Mouth Bagging machines

Open Mouth Bagging machines Vertical packaging machines - VFFS

Vertical packaging machines - VFFS FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information